About High-performance inverter VF-AS3

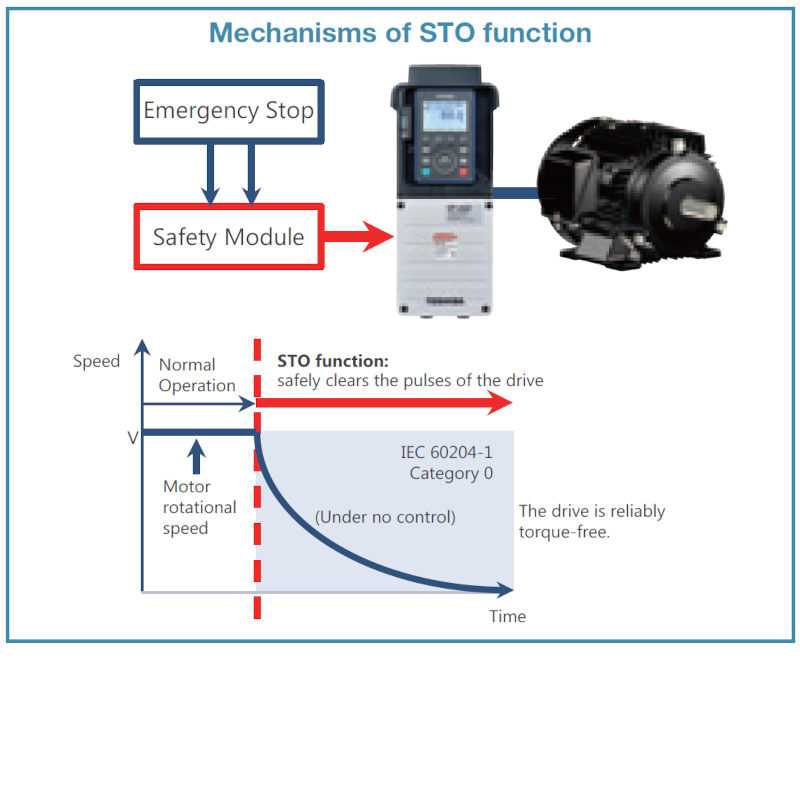

For plant and equipment applications, the inverter has the STO (Safe Torque Off) function compliant with the relevant safety standards to cut off the output with high reliability in an emergency.

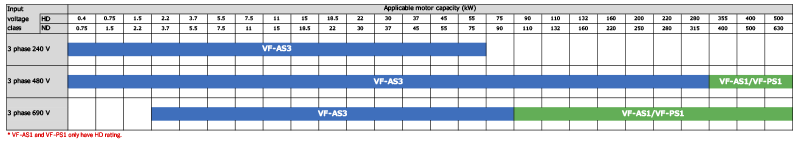

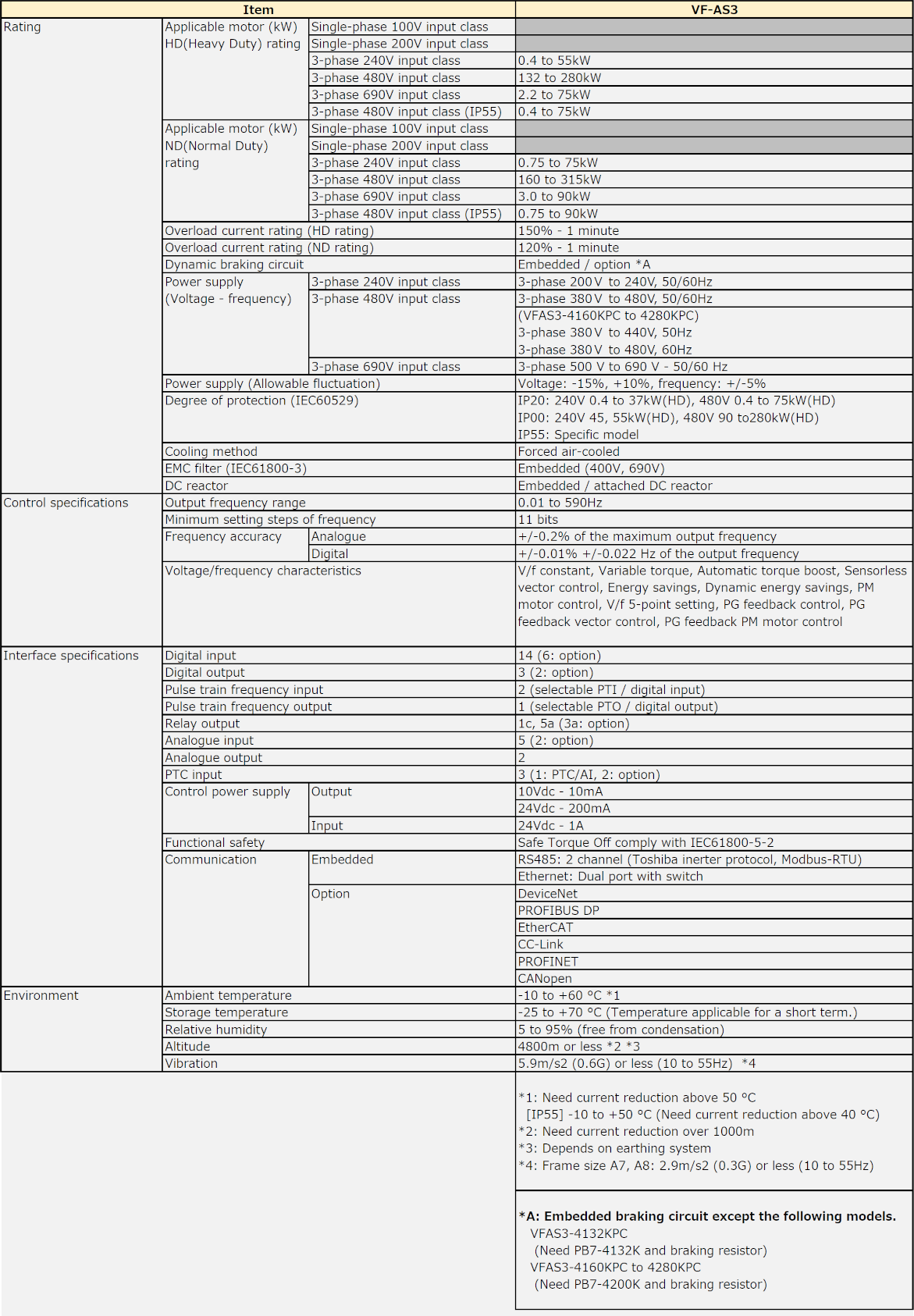

Input voltage class/applicable motor capacity

[HD ratings]

・Three phase 240 V input: 0.4 to 55 kW

・Three-phase 480 V input: 0.4 to 280 kW

・Three-phase 480 V input: 0.4 to 75 kW (IP55)

[ND ratings]

・Three-phase 240 V input: 0.75 to 75 kW

・Three-phase 400 V input: 0.75 to 315 kW

・Three-phase 480 V input: 0.75 to 90 kW (IP55)

Features

- Double ratings (HD ratings/ND ratings)

- A rich set of functions for plant and equipment applications

- The inverter has an LCD operation panel with a large screen as a standard feature.

Double ratings (HD ratings/ND ratings)

HD (Heavy Duty) ratings

(Equivalent to VF-AS1)

・Constant torque applications

・Current overload capacity: 150% for 1 minute

・Applications: Conveyors, cranes, etc.

ND (Normal Duty) ratings

(Equivalent to VF-PS1)

・Reduced load torque applications

・Current overload capacity: 120% for 1 minute

・Applications: Fans, pumps, etc.

A rich set of functions for plant and equipment applications

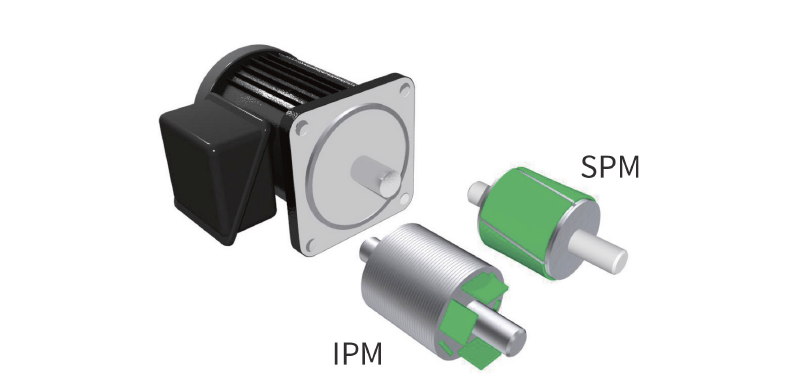

PM motor control

The inverter can drive both IPM and SPM motors. Sensor-equipped and sensor-less models are both supported.

Droop control (load sharing)

When multiple inverters and motors operate a single load, this function prevents the load from concentrating on a specific motor due to the load imbalance.

The inverter has an LCD operation panel with a large screen as a standard feature.

Large LCD screen

The screen can display various types of information (9 languages).

If a trip occurs, the backlight color changes to red to alert the user.

QR code®/video guidance

The QR code® shown on the screen lets you access video-based operation instructions or a description of the action to take in the event of a trip.

Parameter writer function

This function allows you to save and copy the parameters.

Adopts

- Improved environmental durability

- Long-life design offering an expected design life of as many as 10 years

- Reducing PLCs leads to space and cost savings.

- Reduction in the adjustment time

- Reduction in maintenance costs

Improved environmental durability

Comply with the chemicals (3C3)/dust (3S3) standards of IEC60721-3-3. (Frame size A6 or smaller)

The inverter is operable at an ambient temperature of -15 to +60°C. (Frame size A7 and A8: -10 to 60°C)

Long-life design offering an expected design life of as many as 10 years

The use of a long-life cooling fan (*1), main circuit capacitor and control board capacitor enables long-life design offering an expected design life of as many as 10 years (*2).

(*1) 5 years for the cooling fans of frame size A7 and A8

(*2) Annual average ambient temperature: 40°C; output current: 80% of the rated current; relative humidity: 65%; when remaining in operation 24 hours a day, 365 days a year. The expected design life is a calculated value, not a guaranteed value.

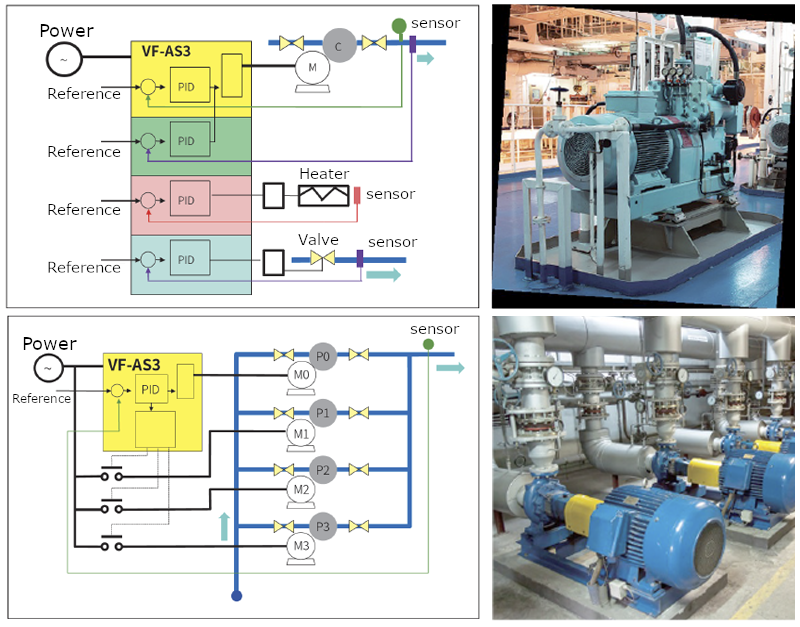

Reducing PLCs leads to space and cost savings.

- Four-PID control function

The inverter has two PID controls for driving the motor and another two independent PID controls, making it possible to also control the peripheral devices, such as valves and heaters, simultaneously. - Multi-pump function

The function can control up to 10 pump motors (extension terminal box option) in terms of the flow rate, pressure, keeping the temperature constant, etc. - Calendar function

The real-time clock (RTC), which manages the year, month, day of month, day of week and hour data, allows you to start or stop the operation at a specified time. - My Function

The My Function built in the inverter handles part of the external circuit consisting of relays, PLC and other components to simplify the system.

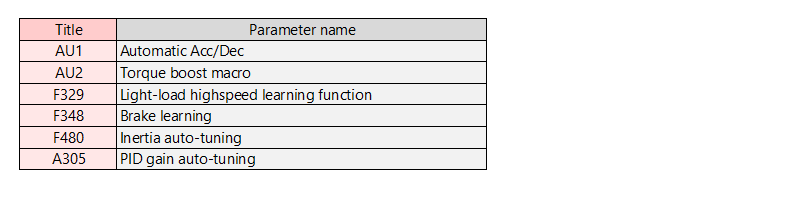

Reduction in the adjustment time

You can auto-tune the motor constants, set the load inertia moment automatically, adjust the PID gains automatically and set the braking and light-load high-speed operation functions of a lifting machine automatically, among other things. This enables optimum adjustment and a reduction in the adjustment time.

Reduction in maintenance costs

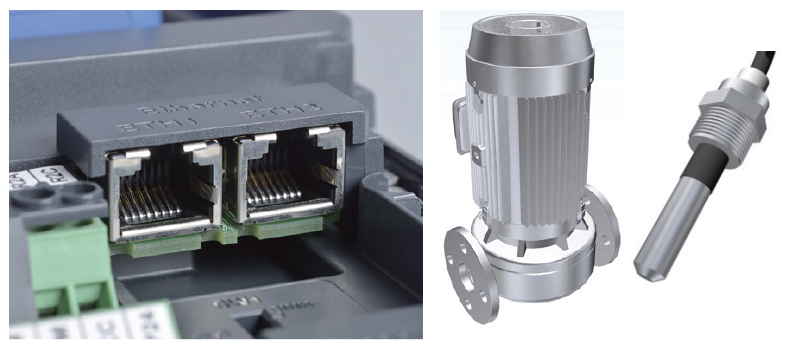

Remote monitoring using the Ethernet communication, which is supported as a standard feature, eliminates the need for on-site checks and operations.

The operation status of the peripheral devices can also be monitored remotely by connecting a sensor to the inverter and using the inverter as an IoT terminal.

Performance

- Energy-saving effect and CO2 reduction

- Suppression of harmonics and improvement in the power factor

- Easy replacement from the existing VF-AS1 model

- Capable of cutting off the output in compliance with safety standards

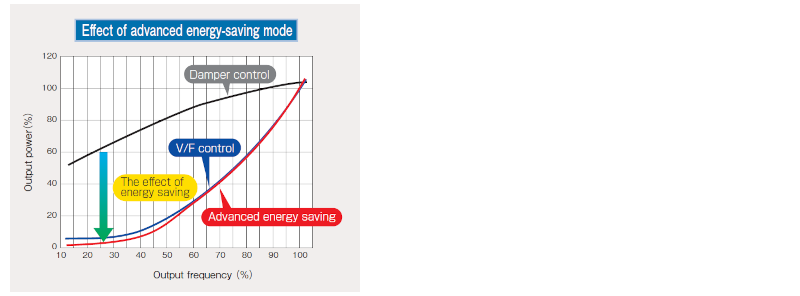

Energy-saving effect and CO2 reduction

When the inverter controls the air volume and flow rate of the general fans and pumps, the shaft power lowers, which saves energy.

Suppression of harmonics and improvement in the power factor

The built-in or optional DC reactor suppresses harmonics while improving the power factor. Also, since the input current becomes small, this design is friendly to the power system and peripheral devices.

・An input power factor over 94%, specified in the Standard Specifications for. Public Works Construction (2019 Edition) supervised by the Ministry of Land, Infrastructure, Transport and Tourism, has been achieved.

(The input rector and DC reactor are required.)

・Built-in/attached DC reactor as a standard feature.

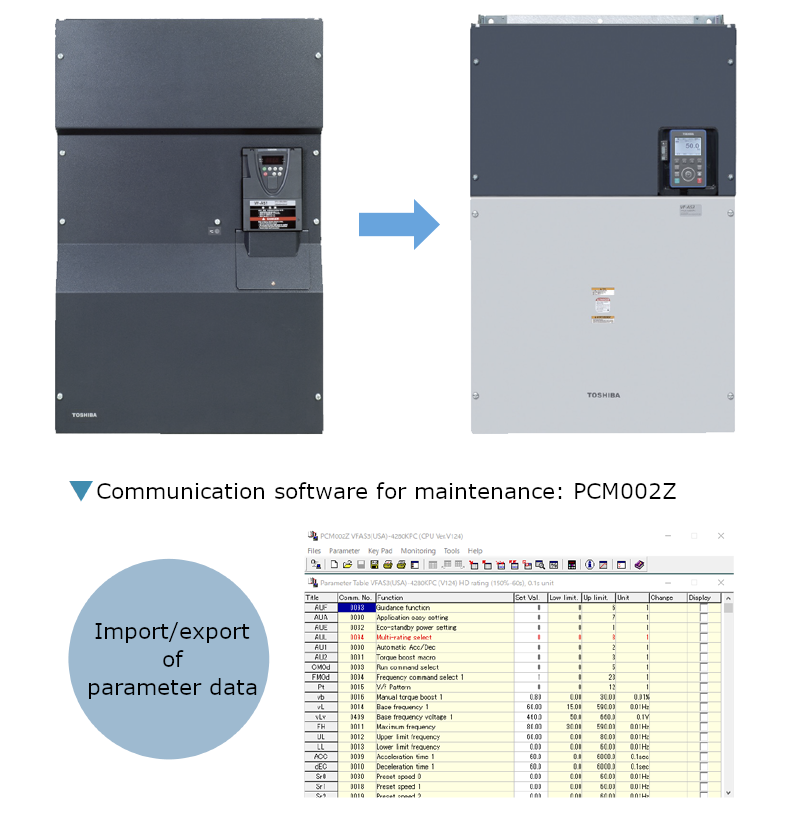

Easy replacement from the existing VF-AS1 model

・The installation dimensions are compatible.

・The parameters*1 set for the existing models VF-AS1 and VF-PS1 can be converted easily to the VF-AS3 parameters by using a dedicated tool.

*1: Reading the parameters from VF-AS1 or VF-PS1 requires the USB001Z option.

Capable of cutting off the output in compliance with safety standards

The inverter features the STO (Safe Torque Off) function compliant with the relevant safety standards and can cut off the output with high reliability in an emergency. The STO function reduces the motor torque close to zero in a safe manner and controls the motor to prevent it from starting inadvertently.

This function is compliant with the IEC61800-5-2 and IEC61508 SIL3 safety standards.

High-performance inverter VF-AS3 Spec

Input voltage classes and applicable motor capacity range

[HD rating] Overload capacity: 150% for 1 minute

Three phase 240 V input: 0.4 to 55 kW

Three-phase 480 V input: 0.4 to 280 kW

[ND rating] Overload capacity: 120% for 1 minute

Three-phase 240 V input: 0.75 to 75 kW

Three-phase 480 V input: 0.75 to 315 kW

Reviews

There are no reviews yet.