COMBIVERT S6

Implement new machine concepts with enhanced performance, communication and integrated safety requirements. Specifically developed for servo applications in a compact book format, the COMBIVERT S6 expands KEB’s product range. This modern, compact yet flexible servo controller is designed for a rated current of 2.6 A to 12 A, and comes in two housing sizes. The servo inverters control a wide range of motor technologies, with or without encoder operation, and – depending on the application – feature scalable, high-performance safety functions.

Highlights

- Functional consistency across the entire power range

- Low-leakage current network filter (< 5 mA) integrated, optionally available without a filter

- High overload for the best dynamics

- Book format for space-saving installation in the control cabinet

- Various options for motors, encoders and communication

- Precision and the highest level of repeatability

- Integrated safety technology

- Can be used in a wide range of applications

Technical data

| Power class | 1-phase 230 V | 3-phase 400 V | |

|---|---|---|---|

| Power range | 0.75 kW and 1.5 kW | 0.75 kW … 7.5 kW | |

| Rated currents | 4 A and 7 A | 2.6 A … 16,5 A | |

| Peak currents (3 s / 60 s) | 2 x In / 1.5 x In | 2.5 x In / 2 x In |

| Device variant | COMPACT | APPLICATION | PRO |

|---|---|---|---|

| Fieldbus communication | EtherCAT or VARAN | EtherCAT, PROFINET (IRT), EtherNet/IP, POWERLINK, Modbus/TCP | EtherCAT, PROFINET, ModBus/TCP |

| Communication interfaces | CAN, diagnosis RS485/232 | CAN, diagnosis RS485/232 | CAN, diagnosis RS485/232, Ethernet, ModBus/RTU |

| Functional Safety | STO | STO, SBC and optional encoder-based speed/position-dependent safety functions | STO, SBC and encoderless speed-dependent safety functions |

| Safety profile | — | Safety over EtherCAT (FSoE), PROFIsafe | Safety over EtherCAT (FSoE) |

| Encoder interfaces | Multi-encoder | Multi-encoder | Multi-encoder optional |

Cooling

Air-cooled built-in variant

COMBIVERT S6 from 0.75 kW

Communication

| Type | |

|---|---|

| Real-time Ethernet interface | EtherCAT, PROFINET, EtherNet/IP, ModBus TCP, POWERLINK, VARAN |

| Communication interface | CAN, Diagnostic interface RS485/232, Ethernet |

| Drive profile | CiA 402 (IEC 61800-7) |

| Safety profile | Safety over EtherCAT (FSoE), PROFIsafe |

| Cyclic fieldbus cycle time | EtherCAT up to 250 µs (125 µs on request) PROFINET, EtherNet/IP, ModBus/TCP, POWERLINK, VARAN up to 400 µs |

| Process data size | EtherCAT up to 32 objects / 64 Byte, PROFINET, EtherNet/IP, ModBus/TCP, POWERLINK, VARAN up to 8 objects / 32 Byte |

| Fieldbus Ethernet diagnosis | EoE (Ethernet over EtherCAT), PROFINET Ethernet channel, EtherNet/IP Ethernet diagnostic channel, Modbus/TCP Ethernet diagnostic channel |

| Serial diagnostic interface | DIN 66019 for connection to diagnostic tools (e.g. COMBIVIS) or an operator |

| Operators / Adapters | LCD operator, Ethernet operator, USB operator, Bluetooth adapter |

| Tools | COMBIVIS 6, COMBIVIS studio 6, COMBIVIS mobile, COMBIVIS Command Line Interface |

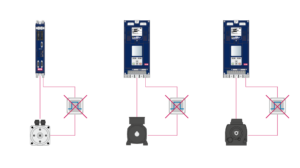

Functional Safety

What is the objective of functional safety? The short answer is to minimise the risks posed by technical equipment to people and the environment. Functionally safe system solutions for machines and plants are based on consistent architecture right through to the mechanical interface. Certified hardware and software isare used to simplify project planning and the development of applications with safety solutions.

COMBIVERT F6 drives offer scalable safety functions directly in the drive controller – with or without encoders. Safety functions and limit values can be flexibly adjusted via digital I/Os and/or the “Safety over EtherCAT” (FSoE) or PROFIsafe safety profile.

- Available for the entire COMBIVERT F6 power range

- Safety functions that can be used with or without encoders

- Up to eight safety configurations per function

- For operating various motor technologies such as ASM, PM, IPM, SyncRel

- Safety functions certified to SIL 3 in accordance with IEC 61508, or to PL e in accordance with ISO 13849

- “Safety over EtherCAT (FSoE)” or PROFIsafe safety profile

- Fast release times

Device variants

Softwarefeatures

| Basics | Flexibility | Highlights |

|---|---|---|

| U/f functionalities | Operation of asynchronous, synchronous (SMM/IPM), synchronous reluctance motors, high-speed motors, high-torque motors, linear motors | Blockade detection |

| Brake handling | Evaluation of different types of encoders: TTL, HTL, Resolver, SinCos, EnDat, Hiperface, BiSS | |

| Quick stop/error reaction | Modes of operation: Velocity, Profile Position, Cyclic Sync Velocity, Cyclic Sync Position, Cyclic Sync Torque, Homing, Jog Mode | Non-linear torque feed forward |

| Device memory/ Recipe management | Anti-Cogging | |

| PID controller | AiSCL (Asynchronous single current closed loop) | |

| Motor/rotor identification | Power-off function (for all motor types) | |

| Index positioning | Servo pump control | |

| Position standstill controller | High output frequencies (variant if applicable) | |

| Rotary table function | CAN-cross-communication (device variant APPLICATION and PRO) | |

| Touch probe function | ||

| Drive software update | ||

| and much more. |

Technology

profile Position Mode CIA 402

The drive profile according to CiA402 provides a standardised platform for drive controller-based automation. This is achieved by means of the modes of operation specified in the profile, in particular also by the Profile Position Mode. The resulting relief of the PLC and cost optimisation with direct, undelayed access to the application enable economical and high-quality application solutions – consistent and manufacturer-independent.

SENSORLESS CONTROL (SCL/ASCL/ASiCL)

Sensorless closed-loop operation and maximum dynamics – without lowering speed during load fluctuations. This is made possible by KEB’s sensorless control methods ASCL (Asynchronous Sensorless Closed Loop) and SCL (Sensorless Closed Loop), regardless of whether asynchronous, synchronous, synchronous reluctance or IPM motors are involved. With ASiCL (Asynchronous single current closed loop), KEB also provides a complementary solution which ensures excellent shaft performance with high torque even in the low-speed range. The motor model also takes care of positioning during subordinate positioning tasks.

High-speed applications

Whether for asynchronous, synchronous, synchronous reluctance or IPM motors: All types of motors can be controlled and operated highly dynamically without encoders by the COMBIVERT F6 or COMBIVERT S6 drive controllers at high speeds of up to 120,000 rpm using the ASCL or SCL method. Depending on individual requirements, this is possible with or without encoder. This means that nothing stands in the way of using motors in high-speed applications.

Reviews

There are no reviews yet.